Hệ thống chiết xuất dùng dung môi 100 lít

| No. | Equipment | Models and Key Parameter | Quantity | Notes |

|---|---|---|---|---|

| 1 | Volume of Extraction Pot | 5L/ 20L/ 50L/ 100L/ 150L/ 200L | 1 | With Heating Jacket |

| 2 |

Separation Tank | 5L/ 20L/ 50L/ 100L/ 150L/ 200L | 1 | With Heating Jacket |

| 3 | Buffer Tank | 5L/ 20L/ 50L/ 100L/ 150L/ 200L | 1 | With Heating Jacket |

| 4 | Condenser | 1m²/ 2m²/ 5m²/ 8m²/ 10m² | 1 | Cool Water |

| 5 | Solvent Pot | 19L/ 29L/ 59L/ 119L/ 159L | 1 | With Solvent Exchange Unit |

| 6 | Gauge Tank | 1L/ 15L/ 45L/ 95L/ 145L | 1 | With Measurement Scale |

| 7 | Heater | 6kw | 1 | Electrical Heating |

| 8 | Hot Water Tank | Size:300*500*500 | 1 | Explosion-proof heater: 5KW |

| 9 | Hot Water Pump | 1 | Explosion-Proof Motor:0.75KW | |

| 10 | Diaphragm compressor | 1 | Explosion-Proof Motor:5.5KW | |

| 11 | Distribution Box | 400*600 | 1 | |

| 12 | Switch Cabinet | 400*500 | 1 |

Oil, Oleoresin, Extractum and Defatted Protein

Oil & oleoresin, extractum and defatted protein are the products you can get directly fromt he extraction machine. First of all, let's see what's the difference between oil and extractum products. For oil seeds and crops, oil products can be extracted directly by the small unit. For flower, herbal and spice, the product is pasty extractum or Oleoresin. If you want to get final essential oil, dewaxing device is needed additionaly. For pigment extraction, you can only get pasty extractum, after-treatment equipment is needed for final purification.

Oil Products

Extractum Products

Oleoresin

Defatted Protein Powder

Extracting Process of Pilot Unit

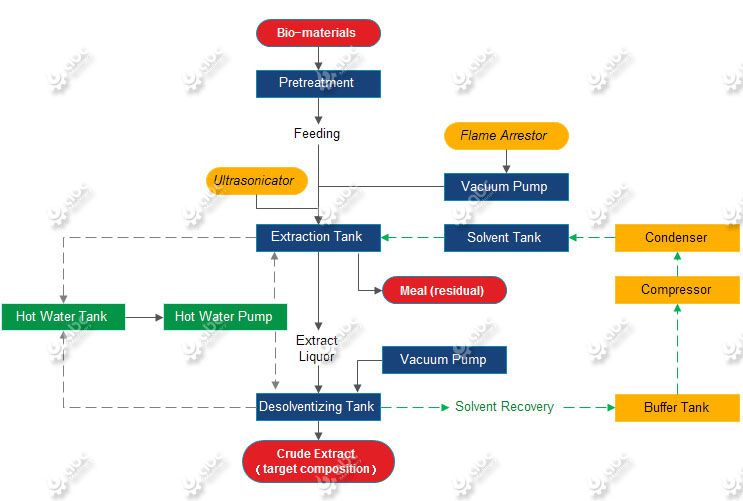

Flow Chart of Essential Solvent Extraction Kit

The pilot solvent extraction unit is the best choice for essential oil extraction testing. It adopts low temperature subcritical biological extraction technology to process raw materials. The main solvents in application are liquid propane, butane, dimethyl ether, R134a and liquid ammonia. Under room temperature (low temperature) and certain pressure, it utilizes liquefied sub-critical solvents to process raw materials through countercurrent extraction, further obtains the extract liquor (liquid phrase) and raffinate (solid phrase). The solvents in extract liquor will be separated with target composition through vaporization in the process of distilling (vaporizing), which brings the final products. Meanwhile, the solvents absorbed in the raffinate, also refers to the extracted material, will be distilled out, and the raffinate through distilling will be become another product. It’s also worth mentioning that vaporized solvents can be liquefied for recycle uses. The whole process is going under room temperature, therefore, thermosensitive substance within raw material can be better protected.

Technical Features of Mini Solvent Extraction Unit

- Advanced and careful design: it’s equipped PLC computer control and features quick-opening structure.

- It automatically controls the ratio of material and solvent, extraction time, extraction temperature, and extraction pressure.

- It is pretty easy to operate and offers precise data.

- It’s widely used among scientific research institutions and colleges.